Contact

Dynasty Metal Additive Manufacturing Systems Co. Ltd

TEL:+86-029-8911 7729

Fax:+86-029-8911 7729

Email:Sales@prozasensor.com

Technical FAQ

Home - Support - Technical FAQ

1. What is Ingress Protection (IP)?

The IP rate identifies the Ingress Protection against humidity and dust. The IP level is described by 2 two figures: the first one is referred to the protection level against dust, the second against water. The Ingress Protection level is an international standard and it is utilized to measure the waterproof ness of any electronic products. Devices with a higher IP level keep the internal components safe and clean.

The meanings of the numbers are given in the following table:

2. What is Pressure Sensor?

Pressure sensors are what they sound like: devices used to measure pressure. They can be used to measure the flow of liquid, the weight or force exerted by one object on another, atmospheric pressure or anything else involving force. A pressure sensor can be as simple as a spring scale, which swings an arrow when pressure is applied to it. Many modern pressure sensors are much more sensitive than scales, and give an accurate output that can be measured electronically.

3. What is Piezoresistive Pressure Sensor?

Silicon-based piezoresistive pressure sensors are made from a thin diaphragm in which resistors are embedded to form a Wheatstone bridge. When pressure is applied to the diaphragm, the electrical resistivity changes due to the mechanical stress (piezoresistive effect). If the bridge circuit is supplied with a voltage, a sensor output signal proportional to pressure is generated.

4. What is Silicon?

Silicon offers special benefits when it comes to manufacturing piezoresistive pressure sensor chips. Due to its single crystal structure, it shows no plastic deformation but returns to its original state without deformation after pressure loading. Material fatigue and hysteresis effects are therefore virtually eliminated. The semiconductor resistors implanted in the silicon sensor diaphragm are highly sensitive to even the smallest pressures and allow for full scale ranges of only a few millibars.

5. In terms of pressure type, what categories can pressure sensors be divided into?

Pressure Sensors can be classified in terms of pressure ranges they measure, temperature ranges of operation, and most importantly the type of pressure they measure. In terms of pressure type, pressure sensors can be divided into five categories:

Absolute pressure sensor

This sensor measures the pressure relative to perfect vacuum pressure (0 PSI or no pressure). Atmospheric pressure, is 101.325 kPa (14.7 PSI) at sea level with reference to vacuum.

Gauge pressure sensor

This sensor is used in different applications because it can be calibrated to measure the pressure relative to a given atmospheric pressure at a given location. A tire pressure gauge is an example of gauge pressure indication. When the tire pressure gauge reads 0 PSI, there is really 14.7 PSI (atmospheric pressure) in the tire.

Vacuum pressure sensor

This sensor is used to measure pressure less than the atmospheric pressure at a given location. This has the potential to cause some confusion as industry may refer to a vacuum sensor as one which is referenced to either atmospheric pressure (i.e. measure Negative gauge pressure) or relative to absolute vacuum.

Differential pressure sensor

This sensor measures the difference between two or more pressures introduced as inputs to the sensing unit, for example, measuring the pressure drop across an oil filter. Differential pressure is also used to measure flow or level in pressurized vessels.

Sealed pressure sensor

This sensor is the same as the gauge pressure sensor except that it is previously calibrated by manufacturers to measure pressure relative to sea level pressure.

6. What is Strain Gauge?

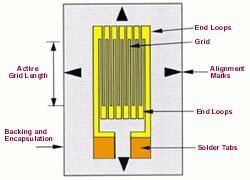

The strain gauge has been in use for many years and is the fundamental sensing element for many types of sensors, including pressure sensors, load cells, torque sensors, position sensors, etc.

The majority of strain gauges are foil types, available in a wide choice of shapes and sizes to suit a variety of applications. They consist of a pattern of resistive foil which is mounted on a backing material. They operate on the principle that as the foil is subjected to stress, the resistance of the foil changes in a defined way.

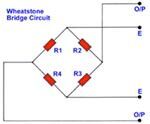

The strain gauge is connected into a Wheatstone Bridge circuit with a combination of four active gauges (full bridge), two gauges (half bridge), or, less commonly, a single gauge (quarter bridge). In the half and quarter circuits, tThe strain gauge is connected into a Wheatstone Bridge circuit with a combination of four active gauges (full bridge), two gauges (half bridge), or, less commonly, a single gauge (quarter bridge). In the half and quarter circuits, the bridge is completed with precision resistors.

The complete Wheatstone Bridge is excited with a stabilised DC supply and with additional conditioning electronics, can be zeroed at the null point of measurement. As stress is applied to the bonded strain gauge, a resistive changes takes place and unbalances the Wheatstone Bridge.

This results in a signal output, related to the stress value. As the signal value is small, (typically a few millivolts) the signal conditioning electronics provides amplification to increase the signal level to 5 to 10 volts, a suitable level for application to external data collection systems such as recorders or PC Data Acquistion and Analysis Systems.

Some of the many Gauge Patterns available

Proza offers extensive ranges of differing patterns to suit a wide variety of applications in research and industrial projects.

Proza also supplys all the necessary accessories including preparation materials, bonding adhesives, connections tags, cable, etc.

As the bonding of strain gauges is a skill and training courses, Proza also offers bonding and calibration services as an in-house service for customers’ application.